Proper tubeless tire maintenance not only extends the lifespan of your tubeless tires but also ensures peak performance and safety. In this comprehensive guide, we’ll delve into the intricacies of tubeless tires. From understanding the core components that make up this innovative assembly to step-by-step maintenance techniques, we ensure you have all the knowledge at your fingertips.

Prepare to explore the critical importance of regular checks and the subtle signs of wear and tear to watch for. By the end of this guide, not only will you be well-versed in the art of maintaining your tubeless tires, but you’ll also be equipped to tackle common challenges with confidence and finesse. Join us as we inflate your know-how and help you roll smoother and longer on the road of tubeless technology.

Contents

Understanding Tubeless Tire Components

To adeptly navigate the world of tubeless tire maintenance, a thorough understanding of its key components is essential. Let’s dissect these integral parts, one by one, illuminating their roles and why they are pivotal in the seamless operation of your tire.

Tire:

The soul of the tubeless system, the tire itself is engineered without the traditional inner tube. Instead, it relies on a robust, airtight seal with the rim to maintain pressure. This configuration not only reduces the tire’s susceptibility to punctures but also provides a plush, more responsive ride. It’s a true paragon of efficiency, cutting down on unnecessary weight while enhancing durability.

Rim:

The rim serves as the tire’s steadfast partner, its design specifically tailored to promote an airtight bond with the tire. Precision here is key; the rim must exhibit a flawless surface to ensure no air escapes. Any imperfections could jeopardize the integrity of the seal, thus the need for periodic inspection and maintenance to fend off corrosion or damage.

Sealant:

The unsung hero of the tubeless setup, the sealant flows freely within the tire, ready to spring into action at the first sign of a breach. Upon encountering a puncture, it quickly coagulates, effectively sealing the hole and preventing air loss. This liquid safeguard not only extends the life of the tire but also offers peace of mind, allowing for longer, uninterrupted rides.

Valve:

Lastly, the valve stands as the tire’s air traffic controller, a small yet crucial component through which air enters and exits the tire. It must remain unobstructed and functional to maintain the desired pressure within the tire. Regular checks are recommended to ensure the valve is free of debris and sealant buildup, which can impede its operation.

By mastering the intricacies of these components, including tubeless tire maintenance, you’re better prepared to maintain and enjoy the full spectrum of benefits offered by tubeless tires. Each element, from tire to valve, plays a pivotal role in the overall performance and longevity of your setup, ensuring that each ride is as smooth and efficient as the last.

Tubeless Tire Benefits

Transitioning to tubeless tires brings a bouquet of benefits that traditional tires struggle to match. Let’s explore these advantages, which not only enhance your riding experience but also contribute to the longevity and performance of your tires.

Reduced Risk of Flats:

Perhaps the most celebrated advantage of tubeless tires is their formidable resistance to flats. The absence of an inner tube eliminates the risk of pinch flats—a common annoyance where the tube is pinched against the rim. Moreover, the sealant within acts as a self-repairing barrier, quickly sealing small punctures almost magically, as they happen. This means fewer interruptions and more continuous, worry-free rides.

Improved Traction:

Tubeless tires allow you to experience the road or trail with an unprecedented level of grip. Without a tube, the tire can conform more easily to the terrain, increasing the contact area. This adaptability ensures that whether you’re cornering hard on a slick street or navigating a rocky path, your traction is consistently maximized.

Lower Rolling Resistance:

Efficiency is key in any ride, and tubeless tires offer just that by reducing rolling resistance. The lighter construction and the absence of friction between the tire and a tube mean you expend less energy to maintain speed. This translates to faster rides with less effort, perfect for those who want to optimize their performance without compromising on comfort.

Ability to Run Lower Tire Pressures:

With these tires, you can venture beyond traditional pressure limits safely. Lower pressures can be utilized without the risk of pinch flats, providing a more comfortable ride. This is particularly advantageous over rough terrains, where the ability to absorb shocks and bumps is enhanced, thus reducing fatigue and increasing control.

By embracing these benefits, riders can significantly enhance their experience, enjoying a blend of reliability, efficiency, and comfort that only tubeless tires can provide. Whether it’s a leisurely cruise through the city or an adventurous jaunt across rugged landscapes, the advantages of going tubeless are palpable and transformative. Keep your riding trouble free by keeping up with your tubeless tire maintenance.

Tubeless Tire Installation

Embarking on the journey of tubeless tire installation marks the beginning of a new chapter in your cycling or driving experience—one filled with fewer flats and a smoother ride. Let’s guide you through this process step-by-step to ensure your installation is both successful and satisfying.

Preparing the Rim and Tire:

Start with a clean slate. Ensure your rim and tire are pristine, free from any dust, dirt, or debris. This initial cleanliness is crucial; even small particles can compromise the seal you’re about to create. Carefully inspect the rim to catch any sharp edges or dents that might impede the tire’s ability to adhere securely.

Installing the Rim Tape Wall to Wall:

The rim tape is fundamental in creating an airtight seal. Use rim tape for tubeless tires. It must cover every inch of the rim’s interior surface, extending from one wall to the other. Make sure the tape is evenly applied, without any bubbles or wrinkles, as these can lead to leaks. Start opposite of the valve hole. Press firmly along the tape to enhance adhesion and ensure a smooth surface. It is recommended to make 2 full rotations, ending at the opposite side of the valve hole.

Installing the Valve:

With the rim tape in place, it’s time to install the valve. Position it precisely at the rim’s valve hole, ensuring it sits tight and flush against the tape. Secure the valve lock nut by hand; over-tightening with tools might damage the rim or the valve itself. Performed correctly, this practice will ensure that your tubeless tire maintenance will be kept to a minimum.

Mounting the Tire:

Now, mount the tire onto the rim. This might require some effort, as tubeless tires often fit tightly to ensure that airtight seal. Start at the section opposite the valve and work your way around, using tire levers if necessary to ease the final section over the rim. Make sure to mount according to any directional arrows you might find.

Adding Sealant:

Finally, it’s time for the sealant—a crucial component that will protect against punctures. The first method is to pour the recommended amount of sealant directly into the tire before fully mounting it. Once added, rotate the tire so that the unmounted portion is at the top. Then, finish mounting the rest of the tire.

Now, rotate the tire to distribute the sealant evenly inside, covering the entire inner surface to safeguard against future leaks. The second method is to mount the entire tire then remove the valve core and inject the recommend amount of sealant. Re-insert the valve core, fill the tire up to the recommended pressure and either rotate the tire several times or do a short ride.

These detailed steps are your blueprint to a successful tubeless tire setup. By following them, you ensure that your tires are not only more resistant to punctures but also optimized for a smoother, more efficient ride. Whether you’re hitting rugged trails or cruising city streets, the benefits of going tubeless are immediately tangible.

Regular Tubeless Tire Maintenance Practices

To ensure your tires continue to provide the optimum performance and durability, regular tubeless tire maintenance is non-negotiable. These routine practices not only prolong the life of your tires but also enhance your riding experience, ensuring every journey is as smooth and safe as the first.

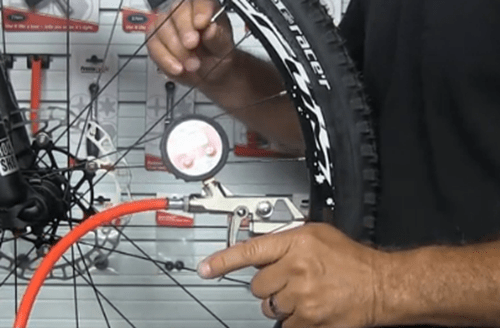

Checking Tire Pressure:

Regularly monitoring your tire pressure is the cornerstone of tubeless tire maintenance. Fluctuations in pressure can affect handling, increase wear and tear, and lead to poor fuel economy. Use a reliable pressure gauge to check the pressure at least once a week, especially before long trips or rides, and adjust according to the manufacturer’s recommendations.

Inspecting for Leaks:

Even with the resilience of tubeless tires, leaks can still occur. Regular tubeless tire maintenance which includes inspections are critical; look for signs of sealant escaping through the tire walls or around the valve, and listen for the faint hissing of escaping air. Early detection of leaks means simpler fixes and less downtime.

Replacing Sealant:

Sealant isn’t forever; it dries out and loses effectiveness. To maintain puncture protection, replace the sealant every 6 to 12 months, depending on your climate and usage. This ensures that your tires are always ready to self-seal should they encounter sharp objects.

Cleaning the Tire and Rim:

Keeping your tires and rims clean isn’t just about aesthetics—it prevents build-up that can affect the tire’s seal and overall performance. Wash both the tires and rims regularly with soapy water, paying special attention to removing any grit or residue from the rim bed where the tire seats, which could prevent a proper seal.

By adhering to these tubeless tire maintenance practices, you ensure that your tires remain a reliable, robust part of your ride. Regular upkeep not only extends the lifespan of your tires but also maximizes your enjoyment and safety on the road or trail. So, keep these tips in mind and make tire maintenance a regular part of your vehicle care routine.

Troubleshooting Common Issues

Even with the best care, these types of tires can encounter issues that affect their performance and longevity. Understanding how to troubleshoot these common problems can save you time and ensure your rides remain smooth and enjoyable. Here’s how to address some of the most typical tubeless tire concerns.

Sealant Drying Out:

If your tire is losing air and the sealant seems to have dried out, it’s time for a refresh. This typically occurs every 6 to 12 months, but environmental factors like heat can accelerate the process. To remedy this, remove the old sealant, clean the inside of the tire thoroughly, and inject new sealant. This simple tubeless tire maintenance step can reinvigorate your tires’ self-sealing capabilities and extend their life.

Leaking Around the Valve:

A common leak point in tubeless setups is around the valve stem. If you notice air escaping here, first ensure the valve core is tightened securely. If the leak persists, remove the valve, clean the base, and apply a small bead of tubeless-specific sealant around the base before re-installing. This should form a tight seal and stop the air from escaping.

Burping Air:

“Burping” occurs when air escapes from between the tire and rim during riding, usually due to a sudden impact or pressure. To prevent this, ensure your tire is properly seated and the rim tape is intact with no gaps or damage. It may also help to slightly increase your tire pressure if you frequently ride on rough terrain.

Tire Bead Not Seating Properly:

If the tire bead doesn’t seat correctly on the rim, it can lead to uneven riding and air loss. This issue often makes a distinct popping sound when inflating. If you encounter this, deflate the tire, apply a light layer of soapy water around the rim and bead to lubricate it, then re-inflate slowly. The soapy water helps the bead slip into place, ensuring a snug fit against the rim. This should take care of any bead seating issues.

By mastering these troubleshooting techniques, you can tackle the most common tubeless tire issues quickly and effectively. Keep your tubeless tire maintenance on track to ensure your tires perform at their best.

Conclusion

As we wrap up our comprehensive guide on tubeless tire maintenance, let’s briefly revisit the key insights and best practices that can help you maximize the longevity and performance of your tubeless tires. From understanding the essential components to mastering the installation process, and embracing regular maintenance routines, each step is crucial for ensuring optimal functionality and durability of your tires.

Tire maintenance is not just about following steps; it’s about fostering a relationship with your ride that enhances every journey. Regular checks, timely sealant refreshes, and proper cleaning can seem mundane, but they are the rituals that keep the wheels turning smoothly and reliably.

Remember, the benefits of tubeless tires—such as reduced risk of flats, improved traction, and the freedom to tailor tire pressure for various terrains—are only fully realized through diligent care. These advantages make every effort worth it, transforming each ride into a more enjoyable and efficient experience.

So, take these tips to heart. Regular tubeless tire maintenance isn’t just a chore; it’s a pathway to uninterrupted adventures and the peace of mind that comes with knowing your tires are in peak condition. Keep riding, keep maintaining, and continue to enjoy the enhanced performance that only tubeless tires can provide.

|

We earn from qualified Amazon purchases with NO cost to you. ANY item that you need or were going to purchased anyway through any of our links, helps support this site. Thank you for your support!